You can find two various kinds of H on the market. There’s a one part H and a two part H. The 2 part H might be known as simple H or as a foundation and cap. They fundamentally accomplish the exact same function – joining two blankets of polycarbonate side to side. There are numerous fundamental variations, but the most significant one is how they’re installed.

One part H’s can be purchased in apparent polycarbonate. Some makers will present them in bronze and ice also to fit their sheets. The very first consideration may be the “dead air” room that’ll be between your two sheets. This is in the biggest market of the H and varies by manufacturer. When developing your frame you need to permit that room to assure proper place of your sheets and never having to cut them down. Once your figure is created you are ready to install the sheets. Fix your two sheets of polycarbonate loosely to your frame permitting the dead air space of the H plus 1/8″ on each area of the H for contraction and expansion.

Start at the end of the blankets and slide your H from the underside of the blankets to the the top of sheets. Some people will suffer with this step. The H’s are tight and designed to be that way. You may need to use a very mild, really decrease soap mixture to lubricate the blankets therefore the H can slide. Also, if more support is required, you may want to take a panel to guard the end of the H and use a sort to go it in to place. Applying one portion H’s on blankets that are more than 12’in total is going to be more difficult than utilizing the 2 portion H.

Two part H’s, or base and caps are available in clear polycarbonate or aluminum. Some producers may offer them in bronze and ice to fit their sheets. The polycarbonate and aluminum can ostensibly mount in the exact same basic manner. There’s also a “dead air” place in these profiles. The base is attached to your frame. After this you set your polycarbonate blankets on either side of the H enabling the 1/8″ space on each side for contraction an expansion. The polycarbonate limit will usually “break” on. You can do this utilising the palm of one’s hand or a rubber mallet. The aluminum limit will often screw to the metal base. The 2 portion H’s are generally more costly to use compared to the one part H. But, they’ll save your self a large amount of time all through installation, particularly on longer sheets.

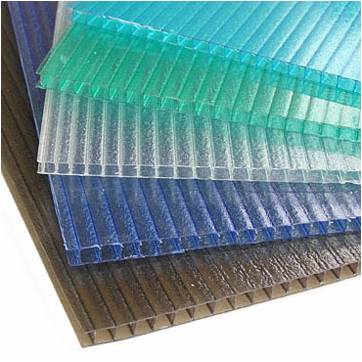

Polycarbonate blankets have now been designed for the 2 house and commercial utilize. It is really flexible material and has many different applications, alongside today you can find and endless choice involving unique glazing designs which often can be utilized applying these types of types involving sheets.

A colorless along with clear plastic-type product that would be applied to change glass is known as polycarbonate. It wound up being created commercially, being an link concerning the thermoplastics household, for you really to contend with die-cast valuable metals. This system may be typically applied during position of glass for skylights because of its impact-resistance in addition to light variables. For skylights, a plastic polycarbonate page is layered with slim coatings applied that make it tolerant to UV rays. This coating, while efficiently because the plastic remaining recyclable, generates polycarbonate sheet manufacturer compliant with eco-friendly creating while an additional in advantage.

The sheeting features a new house that diffuses illumination along side makes dirt nearly hidden, although it is straightforward to completely clean with plane water ways concerning water. It’s usually best to greatly help go through the actual measurements and location concerning your skylight in front of choosing your plastic sheet. Concerning training, skylights are usually certainly not the sole use related to the particular polycarbonate page, as it enables contractors flexibility of design having its broad selection of homes that make the theory ideal for plenty of software.